Main Parameters

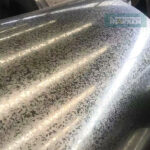

Raw material: Steel coils indurated by cold rolling.

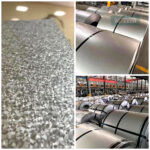

Weight raw material: Max. 20 T/coil.

Weight final product: Max. 15 T/coil.

Raw material outer diameter: Ø900 – 1750 mm.

Raw material inner diameter: Ø 508mm/610mm.

Inner diameter final product: Ø 508 mm.

Steel strip thickness: 0.25–1.0 mm.

Steel strip width: 610 – 1250 mm.

Energetic resources: Electric power, gas, steam, water.

Estimated production capacity 200,000 T/year.

Estimated production time: 220 days x 24 hours.

General Introduction

- The maximum production speed is 150 m/min, for the steel strip having the dimensions of 0,4x1100mm, based on the project and the approval for the maximum production speed for the steel strip at this dimensions. Different dimensions of the steel strip will be used a different production speed.

- The minimum production speed is 50m/min.

- The raw material uncoiler and the final product recoiler have a speed limited to 30 –150 m/min.

- The maximum perforation speed is 30 m/min.

- The average galvanizing thickness (both sides) is 180g/m²; zinc thickness regulation limits (both sides) 100 – 300 g/m².

- The condition Zinc coating: normal spangle, spangle-free.

- The quality of the galvanizing coating in according with the national standard GB2518 – 88; while the galvanizing coating does not come off under inspection.

The production line must be equipped with multiple coil adjusting capabilities, if there is no funnel on both sides for leveling, the one-sided deviation must be < ± 1 mm

The production line has function of rewinding final coil in order or in chiasmus.