General Introduction

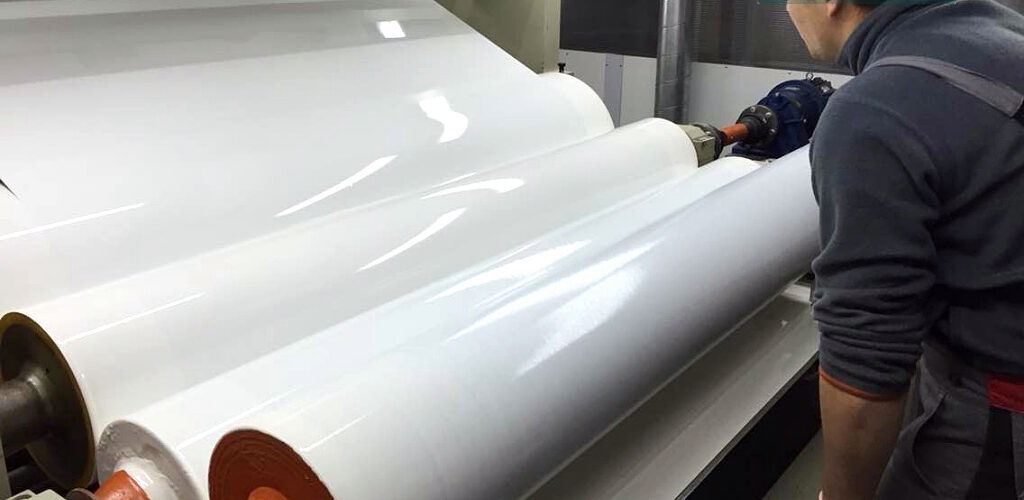

A porous film lay is generated on the aluminum roll surface after anode color is roll coated on the film continuously. After being baked, the bright and elegant or expected aluminum roll is finished. This apparatus can ensure that the color is even and the coating tolerance is less than 3 um, the dope utilization ratio is more than 98%.

- Combined by the tension ratio control system, the coil handling machine can unfold the aluminum roll stably for degreasing, neutralization and chemosynthesized film conversion treatment.

Key Parts Brands &Materials

PLC &Inverter: Siemens, ABB; Hydraulic: Rexroth;

Line Forming Speed

0-50m/min (Standard), 0-100m/min;0-50m/min

Worker Installation Size Power Capacity

Mini 5 Mini 80 * 12 *6 m (Up to final design &specifications) Start from 350KW.

Line General Components

2 Decoilers, Stitcher, accumulator, washing slot, dryer, first painting machine, oven 1#, second painting machine, oven 2#, cooler, accumulator, recoiler, control system, hydraulic system, assistant system.

Optional Components

Fast speed, and full running monitor

Line Designs

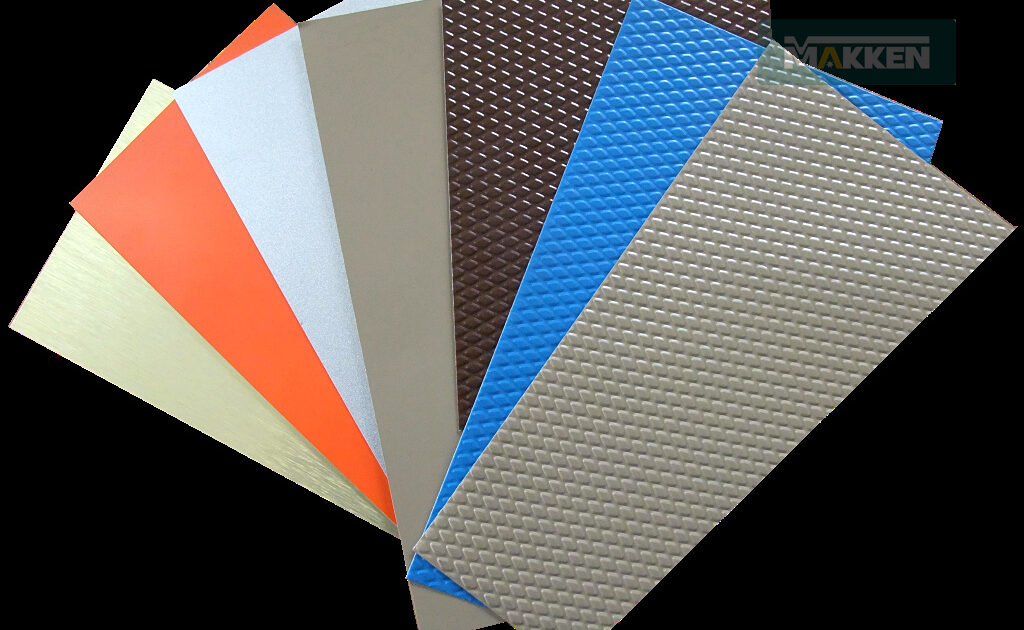

Different coating styles.